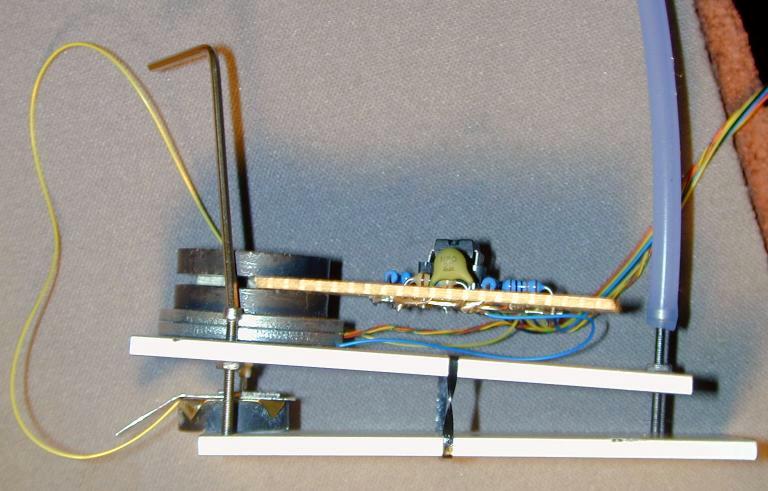

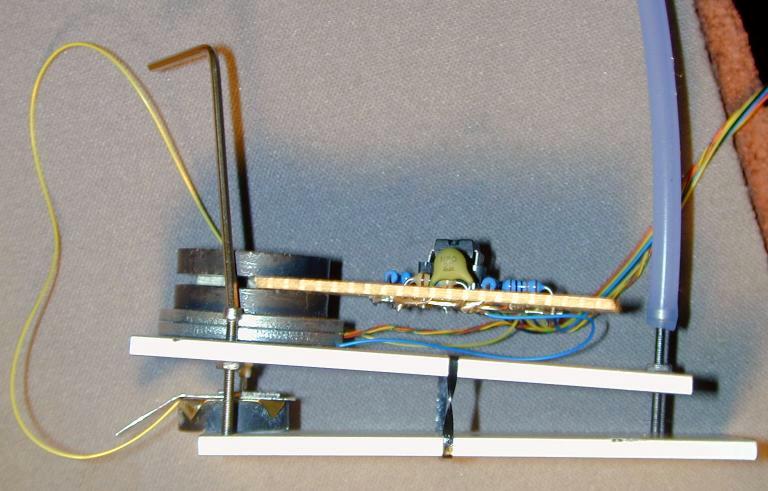

The mechanical approach of

the sample to the tip.

The coarse approach is made with a lever (sample stage) moved by three fine thread machine screws.

I used three UNCF #1-72 screws so at 72 threads per inch that comes to 353

microns (0.353 mm) per turn of the screw. The Z servo range of this unimorph

is only about 3 microns (0.003 mm). The coarse motion of the sample relative

to the tip must be controlled within this 3-micron range to stop the tip

from crashing into the sample. There are two screws on a line about 1 mm

in front of the STM tip. These screws provide a very coarse approach. Because

the tip is about half way between them the Z motion of the sample from these

screws is about 176 microns per turn. The third screw is about 70-mm away

form the line of the first two screws (fulcrum). The Z motion of the tip

is 1/70 of 353 or 5.04 microns per turn. There is only a range of about a

half a turn of the back screw where the electronic servo can control the

tip before the tip crashes. If the screw mounting is loose this range can

be even less. On all commercial microscopes that use this type of approach

at least this back screw is motorized. To keep the design as simple as possible,

I did not do this. Many early Scanning Tunneling Microscopes used this hand

approach technique, using a 40 thread/inch micrometer. It does get frustrating

at times especially when you are used to the commercial machines. If I redo

this I plan to use # 2-56 screws instead because the difference between 0.005

mm per turn and 0.006 mm per turn is not very significant and the screws would

be sturdier and I would also add a motor.

After placing a sample on the sample holder and placing a fresh tip

in the scanner extend the three machine screws all the way down . Then carefully

place the sample stage lever on the scanner holder, being sure the tip does

not touch the sample. I wrapped several rubber bands around the microscope

to hold the two halves together tightly. While looking through a magnifying

glass or long working distance optical microscope adjust the front two coarse

adjustment screws to bring the tip as close as you can to the sample without

touching it. Turn on the electronics and connect the oscilloscope to the tunneling

current signal and Z servo signal. Then slowly turn the back fine adjustment

screw while watching the tunneling current and Z servo on the oscilloscope.

Remember you must stop turning within one half turn of the point where it

first comes into tunneling. Ideally you would like to adjust this screw so

that the Z servo output is near the center of its range.

Home Simple STM Project Home Project Overview Progress

Mechanical Design

Disk Scanner Description How to Make a Disk Scanner Mechanical Approach

Mechanism

Mechanical Bill of Materials Electronics Design Electronics Schematics

Electronics Bill of Materials Operating the STM Images